Navigating Production Challenges: Insights from Disposable Medical Supplies Factories

There are various important things to consider when we make disposable medical supplies. Things like lessons from the workers, new ideas in the industry to be interested in, how we can make production better with real examples of factories and tips when things go wrong down on ground.

Some of the most knowledgeable people working in factories that make disposable medical supplies They have struggled through a lot and acquired the knowledge to solve them as years went by. What is of such great value are their experiences, because allow us to try not make the same mistakes and allows our work to improve as much possible. We can gain invaluable insights by listening to their stories, and we can learn something from them that would help us make our own process much better.

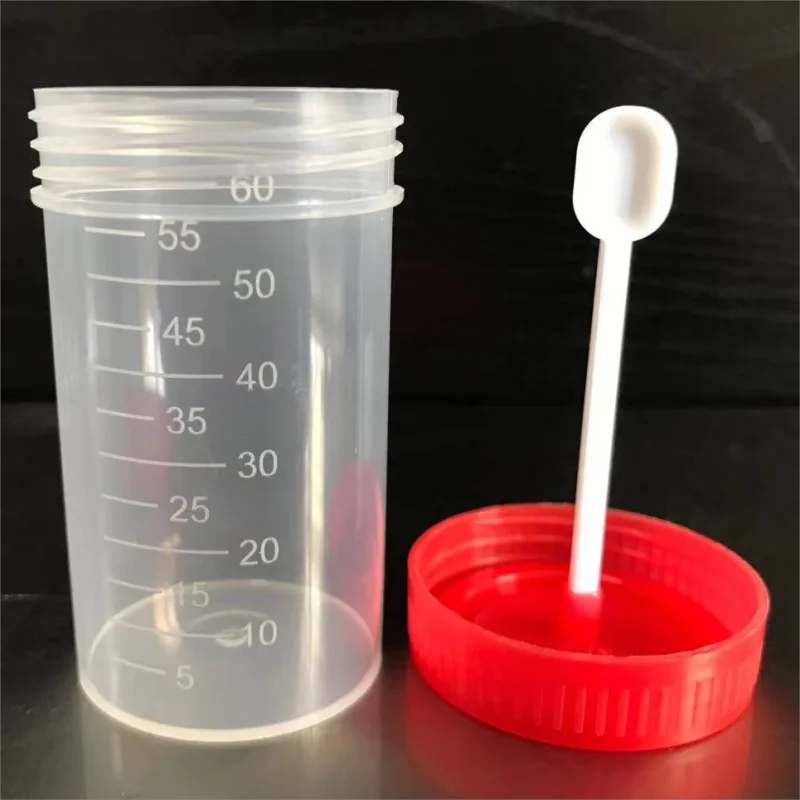

Automation is a new idea which has paved way for smooth functioning in this fraternity. BIOLOGICAL CULTURE VESSEL of the work so you don't have to (instead of by hand) This, in turn can make production far quicker and simpler for workers. For instance, some have robot arms that can be used to package items into boxes or even help make the supplies. These new tools are not only cutting the time spent working, but they also make it safer and more effective for all parties involved.

Having a neat and clean factory production removes every chance of fouling up on anything. This way, workers have free room to move around and products can be easily accessible. So, being well organized will be good for even the production to go faster and smoother which can obviously mean better results. This also implies that the workers have the opportunity to put all their effort on other tasks and not waste time looking for materials or tools whichV suggest its cost effective.

Realworld examples of these SEROLOGICAL PIPETTE help us to understand what it means to work in a facility that produces nonreusabile medical supplies. It will help us to know how the workers learn of their daily challenges, and why they have special clothes wear every time or cleaning everything very well so that no germs reach products. Knowing what it is they do and how to stay safe can help us understand the challenges these workers face each day. It also helps us appreciate how crucial their roles are to patient safety and wellbeing.

It provides useful advice for the resolution of problems that may arise in TRANSFER PIPETTE factories. When the materials do not arrive in time due to supply chain disruptions, workers may have to get creative about utilizing what they already have onhand which degrades production efficiency. When a machine breaks, they might have to rig something quickly as a temporary solution before the repair man comes and fixes them for real. Advice like this is so vital, because it's what keeps the production going when things start to cave or an unexpected curveball strikes.

workers offers tips from their real factory experience, a best practice for production ideas and useful solutions to challenges in disposable medical supplies. Considering all of these aspects, we are able to produce products that aid in making the patients lives a better one and help healthcare workers have seamless care. A full appreciation of that process and who the people are behind it certainly changes how we approach producing those paramount needed items.

Comments

Post a Comment