The Impact of Light Source Selection in Mask Aligners

Selecting the correct light for your mask aligners is very critical to your alignment work. When you need to create precise patterns on minuscule computer chips or other small electronic devices, the light source you use can make a difference — a difference on the nanometer scale, or even smaller.

Knowing how different lights will influence a mask aligner is the foundation to achieve great alignment results. Typical light sources used in mask aligners are mercury lamps, LED lights and UV lamps. Every rectangular to circle grinder is different and all have characteristics that can alter the orientation process. For instance, mercury lamps emit a broad spectrum of light, which allows them to be used for a variety of purposes. It is more energy efficient and can last longer compared to the LED lights. UV lamps emit ultraviolet light, which is good for making tiny patterns.

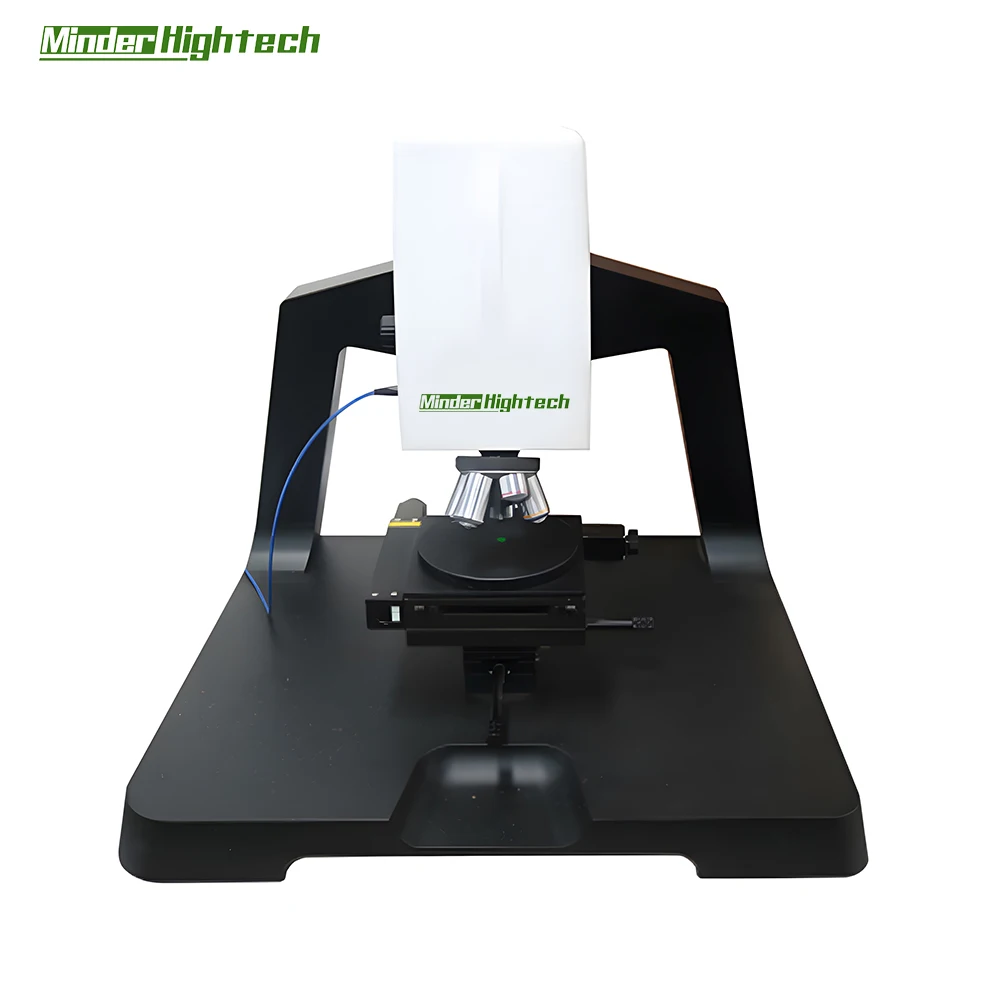

Selecting an appropriate light source for mask alignment is critical. The vacuum soldering system you choose can make a difference in how clear, accurate and good the alignment process goes. Selecting the right light for your mask aligner will ensure that your patterns are accurate and repeatable. Minder-Hightech supplies many specialized light sources for mask aligners so you can find the ideal solution for your projects.

The appropriate light in mask aligners is an essential requirement in order to satisfy the stringent requirements of the semiconductor industry. Technology is evolving fast, and we need good patterns now, more than ever. Of course, with the newest types of vacuum eutectic soldering in your mask aligner, you are able to speed up the alignment of your products and still maintain the level of quality and accuracy as before. Minder-Hightech's premium lights are designed to provide maximum performance for mask aligners delivering superior results for your projects.

Examining how your light influences mask aligner resolution and quality can enable you visualize how other lights impact how well your alignment works. More higher-resolution patterns will require an even, more precise light source to ensure they transfer properly to the surface. You can get better results on your projects by choosing the correct light for your mask aligner, which can improve the sharpness and quality of your patterns. The advanced light sources from Minder-Hightech are specially developed to increase resolution and quality, to assist you in reaching superiour alignment results in your semiconductor application.

In summary, light in mask aligners is crucial for your alignment success. You can increase the sharpness, accuracy, and quality of your patterns and subsequently your projects by choosing the right light for your mask aligner. Minder-Hightech has numerous high-end light sources tailored to Mask-Aligners for outstanding performance and efficiency. With the proper lighting, you can take your alignment to a new level and ensure you are up to the rigorous demands of the semiconductor industry.

Comments

Post a Comment