Why a Reinforced Base is Critical for Large-Scale Injection Molding

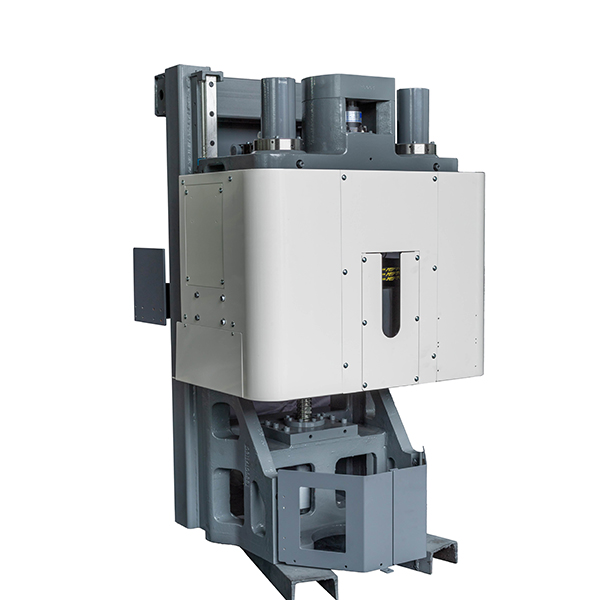

Injection molding is a process for producing products by injecting melted materials, typically made of plastic, metal or rubber, into a mold. While plastic is being shoved into a mold to produce items. This process can create things like toys, containers and parts for machines. At Pingcheng, we understand that a solid foundation is very essential in large injection molding machines.

A sturdy bottom keeps the weight and pressures of these machines in place. And these hydraulic accumulator pressure are heavy, and push very hard when making stuff. This weight and pressure is spread evenly by a good base. If the foundation is weak, the machine can rumble or tip over, risking injury and expensive maintenance.

If a base lacks stability, the machine may vibrate. This shaking can also allow the machine to go off balance, which can hinder the quality of products being produced. Using a strong base, Pingcheng keeps our machine stable and aligned, enabling us to produce good products always.

A stable base also helps keep workers safe. Large heat accumulator often run at pressures topping tens of thousands of pounds per square inch, and this pressure can easily crush hands or arms if maintenacne is negligent. The solid base provides safety and stability, reducing the risk of injury.

The initial investment in a strong base can save money over time. A strong base can prevent not only shaking but also misalignment issues, which can be expensive to rectify. By accumulator low pressure in a strong base now, Pingcheng can reduce its repair bills and ensure our machines run well. This is what enables us to create excellent products for our clients.

A sturdy base is also crucial to making sure products are manufactured effectively and uniformly. The machine works best when it’s in the right spot, and a good base makes sure that’s the case while stuff is getting made, ensuring it all comes out consistently at the other end. At Pingcheng, we know the importance of quality when it comes to producing machines, so we prepare strong bases for our machinery.

Conclusion: A Good Base is Just as Important for large injection molding machines!important. “It takes the load and pressure off, it takes away mistakes, it keeps people safe, it saves you money and it helps make sure product is made well,” he said. Through solid foundations, Pingcheng will maintain good quality and efficiency job in the injection molding.

Comments

Post a Comment